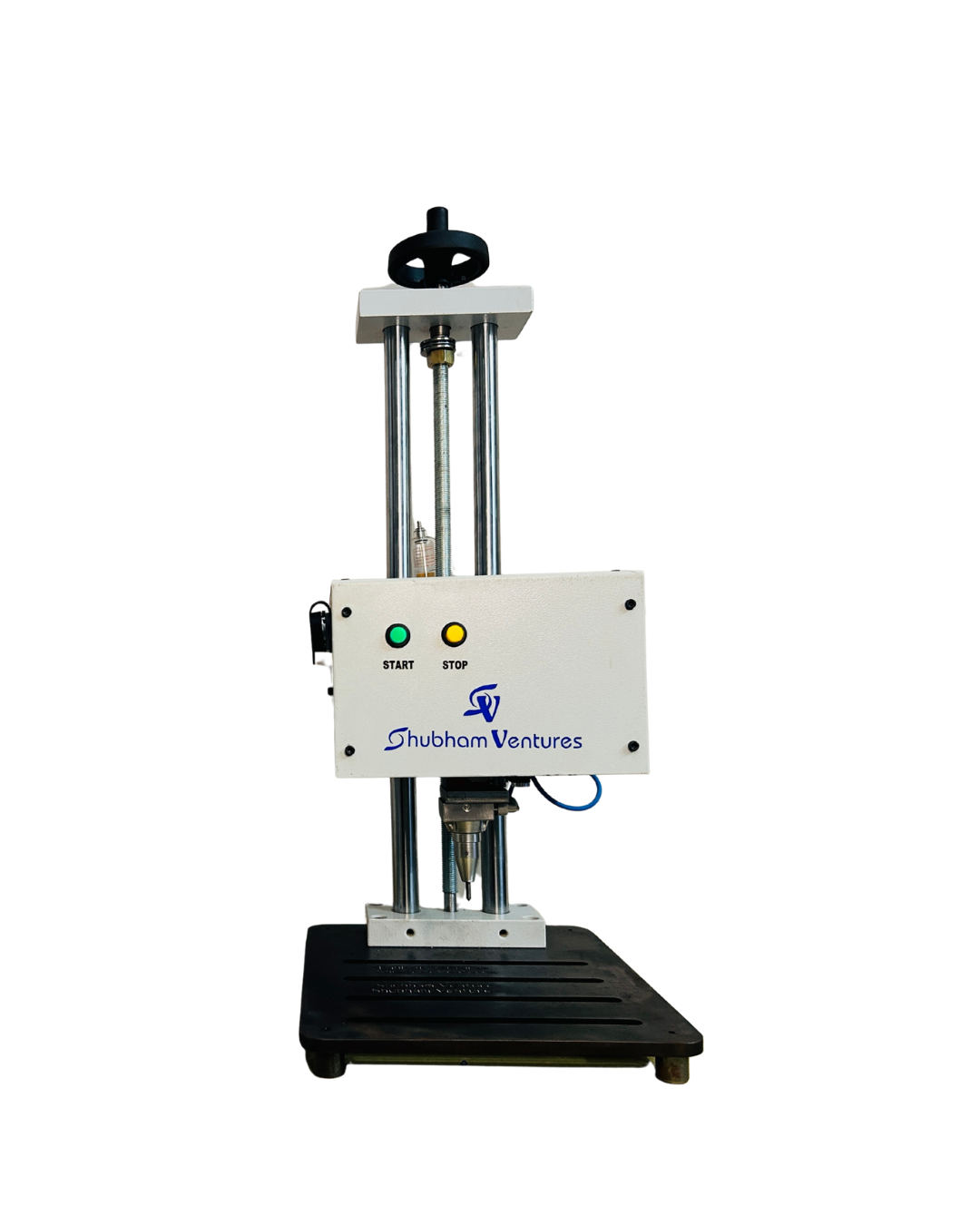

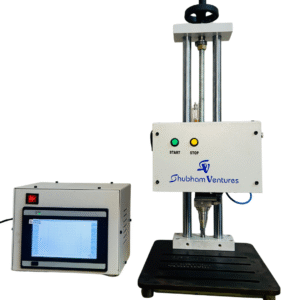

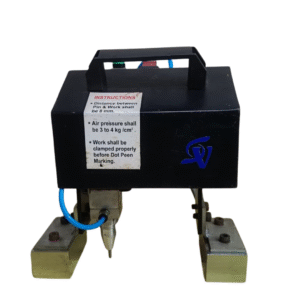

Our dot peen marking machine is designed for industries that need fast, accurate, and permanent marking on metal and plastic parts. This table-top model (without display) connects directly to a computer, giving you complete marking control. Moreover, it offers excellent stability and precision, making it ideal for workshops, factories, fabrication units, and small production setups. The machine delivers consistent dot peen markings for serial numbers, QR codes, barcodes, logos, batch codes, and product identification.

The table-top structure makes the machine compact and easy to place on any workbench. In addition, you can adjust the marking depth depending on the material, which includes steel, aluminum, brass, copper, plastic, and coated surfaces. The marking output is sharp and clear, even during long production cycles. Furthermore, the industrial-grade body ensures durability and smooth operation with minimal maintenance.

This dot peen marking machine supports a wide range of industrial applications. For example, automotive companies use it for engine parts, brackets, gears, and metal tags. Electrical manufacturers use it for circuit boxes, enclosures, and metal plates. Fabrication workshops rely on it for custom branding and part identification. Consequently, this machine improves traceability, product quality, and long-term durability of markings.

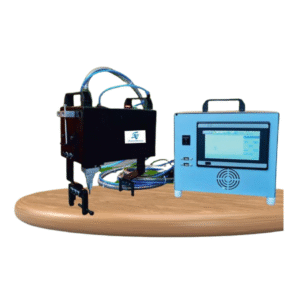

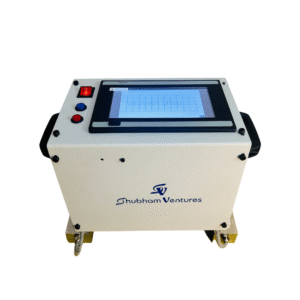

The system works entirely through PC-based software, offering user-friendly controls and high flexibility. Operators can set marking speed, size, angle, and depth based on job requirements. As a result, you get a smooth workflow and professional-grade output every time. Overall, this dot peen marking machine offers precision, durability, and affordability—making it a valuable asset for any industrial environment.