Adapter sleeves are precision-engineered components used to mount bearings on smooth or stepped tapered shafts. They provide a secure and accurate fit that prevents slippage and supports long-term machine performance. Moreover, they simplify the installation process and eliminate the need for additional machining.

These sleeves are made from durable, high-strength steel to handle heavy loads and continuous industrial operation. In addition, their tapered design allows bearings to seat firmly on the shaft using a lock nut, ensuring proper alignment and stable mounting without causing shaft damage.

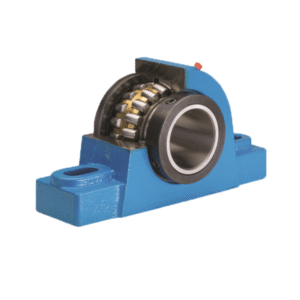

They are widely used in motors, pumps, compressors, conveyors, plummer blocks, gearboxes, and material-handling equipment. For example, engineers commonly use them with spherical roller bearings that require safe and precise mounting. The even pressure distribution protects both the shaft and the bearing from premature wear. Consequently, machines operate smoothly with reduced maintenance.

Adapter sleeves also provide excellent compatibility. Their design fits a wide range of shaft sizes, reducing the need for custom components. Furthermore, their corrosion-resistant finish ensures long service life in dusty, humid, or high-vibration environments.

Installation is simple. The sleeve fits between the shaft and the bearing bore, and tightening the nut locks everything in place. The process is clean, efficient, and minimizes downtime for machinery that undergoes frequent bearing changes. Removal is also easy, making them ideal for equipment that requires regular inspection.

Overall, these sleeves offer secure mounting, long-term durability, and user-friendly installation for modern industrial systems. They remain a trusted choice for technicians and industries looking for safe and reliable bearing mounting solutions.