High-Speed Precision for Demanding Machinery

Angular contact ball bearings are engineered to support combined radial and axial loads while delivering exceptional high-speed performance. Their ball-and-raceway contact angle ensures stability and accurate rotation even under heavy axial pressure. Moreover, their optimized design reduces friction and increases efficiency in precision machines.

Ideal for High-Precision & High-Speed Applications

Industries rely on these bearings for CNC spindle assemblies, pumps, motors, blowers, compressors, gearboxes, and robotics. In addition, angular contact bearings are used in automotive systems, turbine equipment, and precision industrial tools that require consistent accuracy. Their load-handling capability helps maintain smooth rotation under demanding conditions.

Advanced Engineering for Maximum Durability

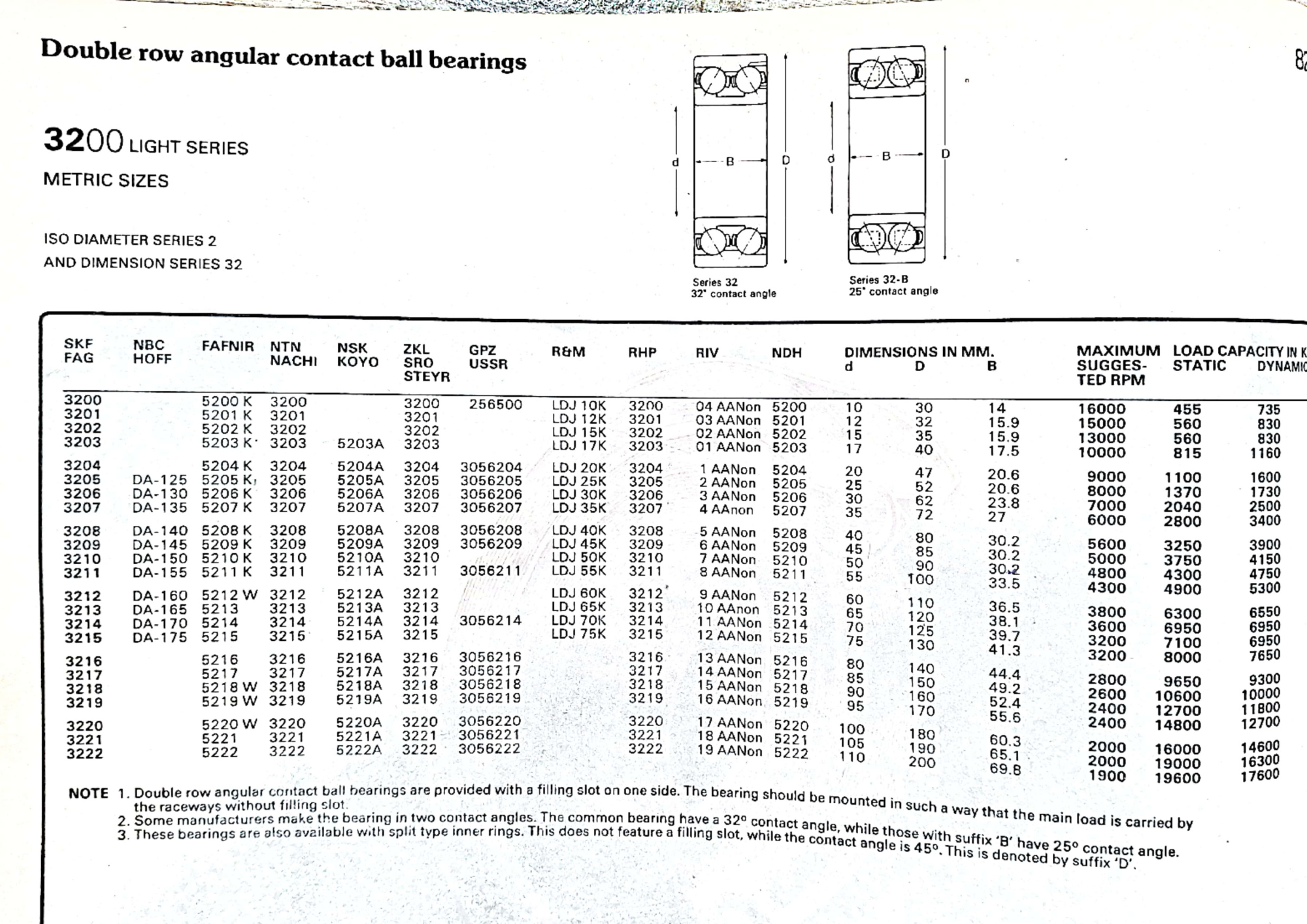

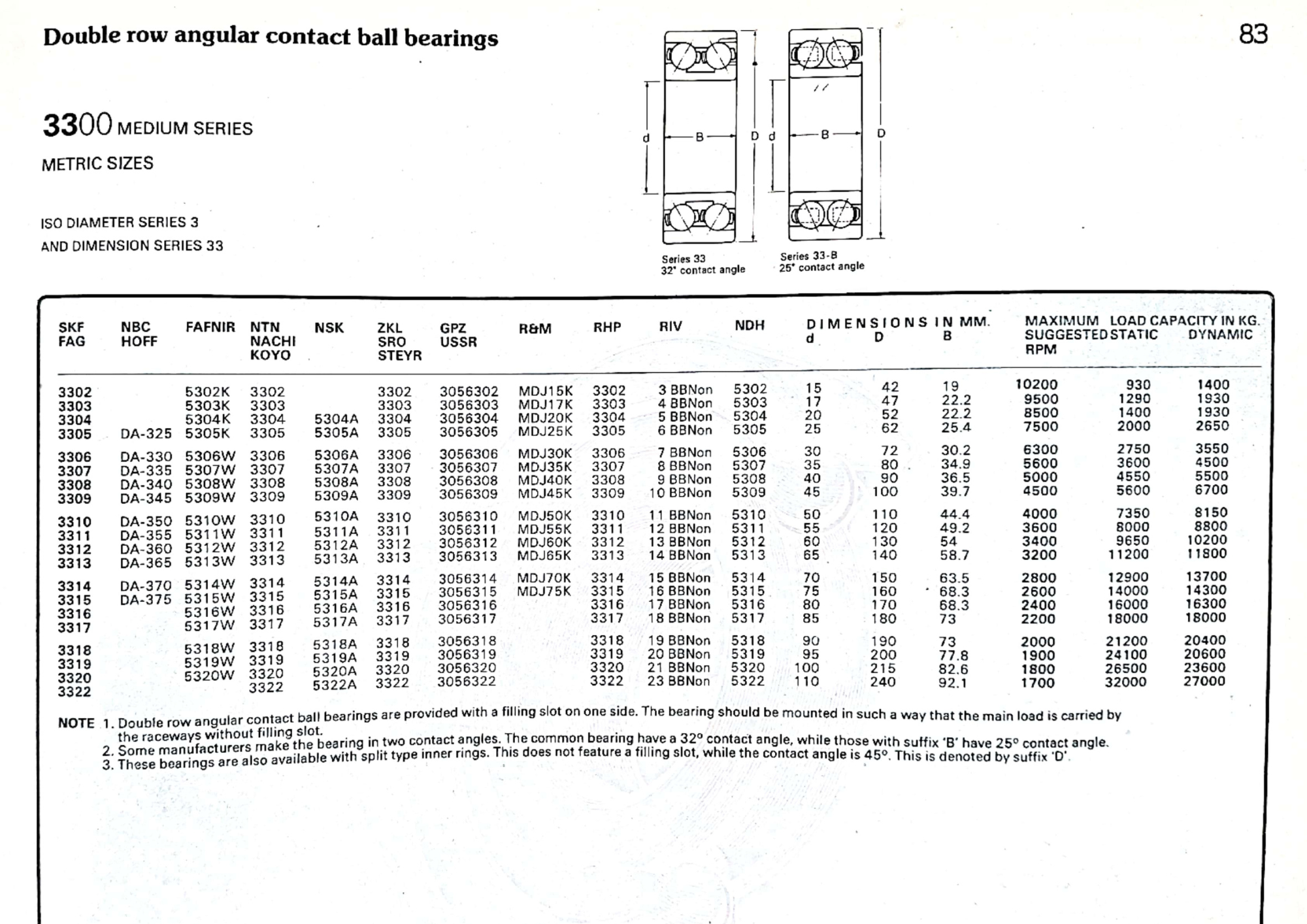

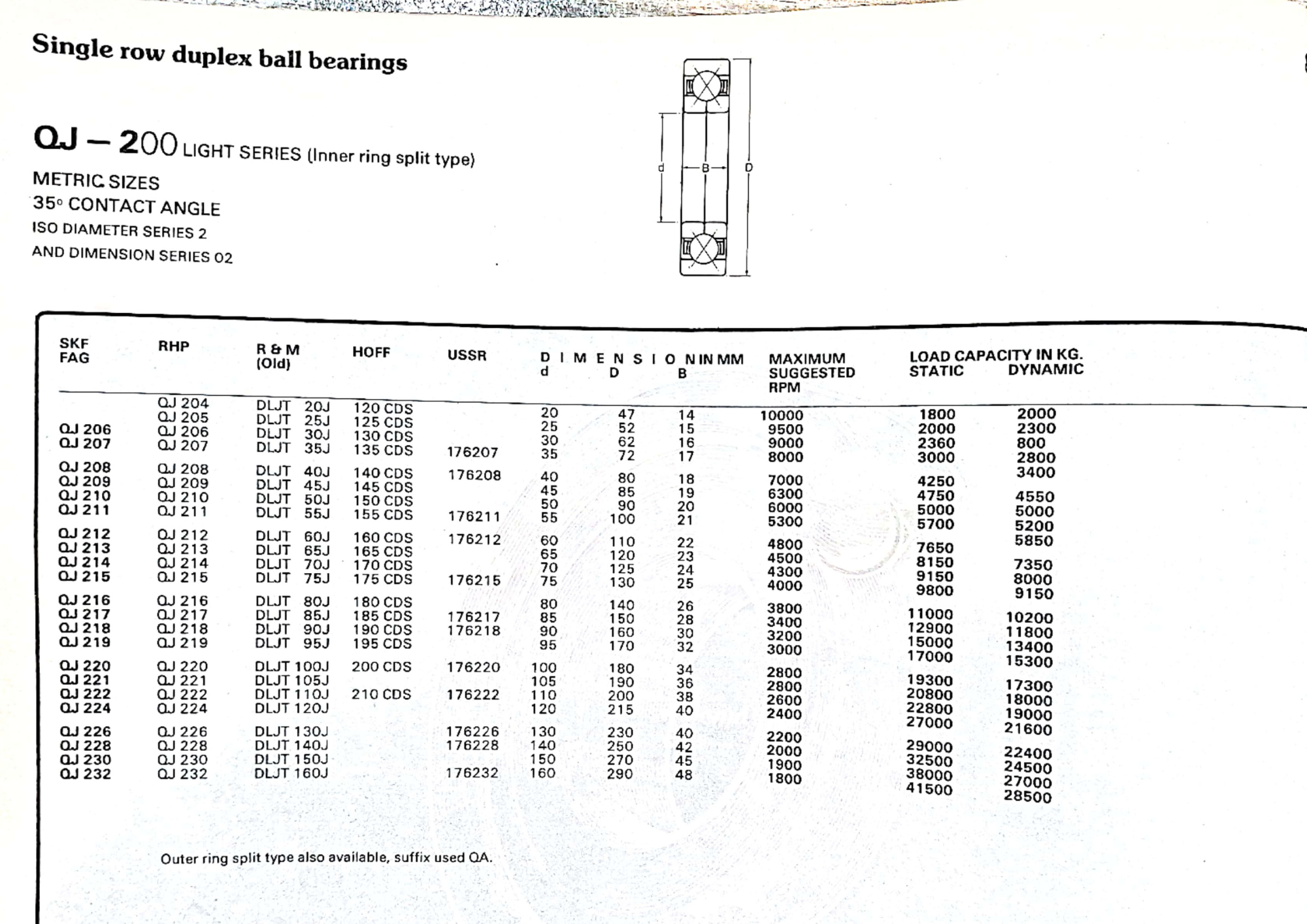

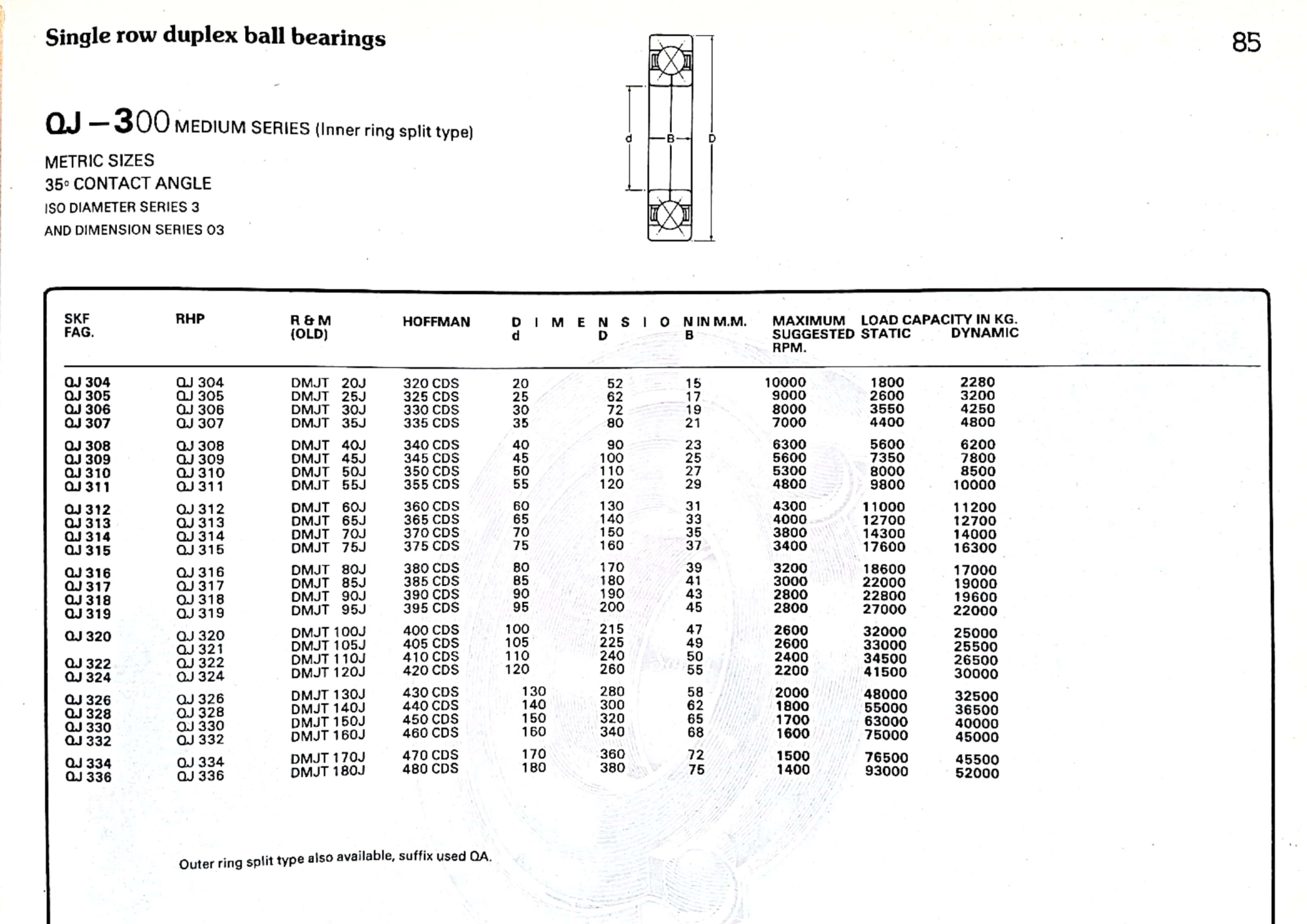

These bearings come in single-row, double-row, and four-point contact designs to support specific load and speed requirements. Their high-quality steel construction enhances strength, while precision-ground raceways reduce vibration and noise.

The contact angle plays a major role in performance. A larger angle supports heavier axial loads, while a smaller angle allows higher speeds. Furthermore, advanced lubrication and sealing systems protect the rolling elements from contaminants, improving overall bearing life.

Smooth Operation & Easy Installation

Angular contact bearings install easily and maintain accurate alignment. They pair well in matched sets for increased load capacity and improved rigidity. Their ability to manage thrust loads makes them essential for machines that operate under rapid acceleration and high-speed rotation. With proper lubrication, these bearings provide consistent, quiet, and long-lasting performance.